| Description |

Model |

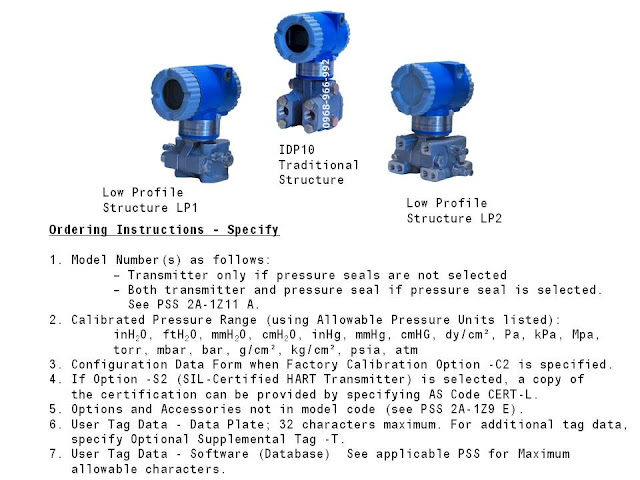

| IDP10 |

= |

Measures The Difference Between Two Pressures And Transmits A Proportional Or Square Root (Flow) Electrical Signal. |

IDP10 |

| ELECTRONICS VERSION AND OUTPUT SIGNAL: |

|

| D |

= |

Intelligent; Digital FoxCom Or 4 To 20 mA, Configurable |

D |

| T |

= |

Intelligent; Digital HART & 4 To 20 mA |

T (b) |

| F |

= |

Intelligent; FOUNDATION Fieldbus |

F |

| A |

= |

4 To 20 mA; Includes Explosionproof Rating And LCD Indicator With Pushbuttons For Calibration, Configuration, Standard Pressure Units, And Rearranging (Excludes Custom Labels And Intrinsic Safety Rating) |

A |

| V |

= |

Voltage Output, 1 To 5 Vdc, Low Power, Including LCD Indicator With Pushbuttons |

V |

| STRUCTURE CODE: |

|

| 10 |

= |

Steel Process Cover, Co-Ni-Cr Sensor, Silicone Fill Fluid |

10 (c) |

| 11 |

= |

Steel Process Cover, Co-Ni-Cr Sensor, Fluorinert Fill Fluid |

11 (c) |

| 12 |

= |

Steel Process Cover, 316L ss Sensor, Silicone Fill Fluid |

12 |

| 13 |

= |

Steel Process Cover, 316L ss Sensor, Fluorinert Fill Fluid |

13 |

| 16 |

= |

Steel Process Cover, Hastelloy C Sensor, Silicone Fill Fluid |

16 |

| 17 |

= |

Steel Process Cover, Hastelloy C Sensor, Fluorinert Fill Fluid |

17 |

| 20 |

= |

316 ss Process Cover, Co-Ni-Cr Sensor, Silicone Fill Fluid |

20 (c) |

| 21 |

= |

316 ss Process Cover, Co-Ni-Cr Sensor, Fluorinert Fill Fluid |

21 (c) |

| 22 |

= |

316 ss Process Cover, 316L ss Sensor, Silicone Fill Fluid |

22 |

| 23 |

= |

316 ss Process Cover, 316L ss Sensor, Fluorinert Fill Fluid |

23 |

| 2G |

= |

316 ss Process Cover, 316L ss Gold Plated Sensor, Silicone Fill Fluid |

2G |

| 24 |

= |

316 ss Process Cover, Monel Sensor, Silicone Fill Fluid |

24 |

| 25 |

= |

316 ss Process Cover, Monel Sensor, Fluorinert Fill Fluid |

25 |

| 26 |

= |

316 ss Process Cover, Hastelloy C Sensor, Silicone Fill Fluid |

26 |

| 27 |

= |

316 ss Process Cover, Hastelloy C Sensor, Fluorinert Fill Fluid |

27 |

| 34 |

= |

Monel Process Cover, Monel Sensor, Silicone Fill Fluid |

34 |

| 35 |

= |

Monel Process Cover, Monel Sensor, Fluorinert Fill Fluid |

35 |

| 46 |

= |

Hastelloy C Process Cover, Hastelloy C Sensor, Silicone Fill Fluid |

46 |

| 47 |

= |

Hastelloy C Process Cover, Hastelloy C Sensor, Fluorinert Fill Fluid |

47 |

| 48 |

= |

Hastelloy C Process Cover, Tantalum Sensor, Silicone Fill Fluid |

48 |

| 49 |

= |

Hastelloy C Process Cover, Tantalum Sensor, Fluorinert Fill Fluid |

49 |

| 78 |

= |

pvdf (Kynar) Process Cover, Tantalum Sensor, Silicone Fill Fluid |

78 |

| 79 |

= |

pvdf (Kynar) Process Cover, Tantalum Sensor, Fluorinert Fill Fluid |

79 |

| LL |

= |

316 ss LP1 Process Cover, 316L ss Sensor, Silicone Fill Fluid |

LL |

| LM |

= |

316 ss LP1 Process Cover, 316L ss Sensor, Fluorinert Fill Fluid |

LM |

| LC |

= |

316 ss LP1 Process Cover, Hastelloy C Sensor, Silicone Fill Fluid |

LC |

| LD |

= |

316 ss LP1 Process Cover, Hastelloy C Sensor, Fluorinert Fill Fluid |

LD |

| 52 |

= |

316 ss LP2 Process Cover, 316L ss Sensor, Silicone Fill Fluid |

52 |

| 53 |

= |

316 ss LP2 Process Cover, 316L ss Sensor, Fluorinert Fill Fluid |

53 |

| 56 |

= |

316 ss LP2 Process Cover, Hastelloy C Sensor, Silicone Fill Fluid |

56 |

| 57 |

= |

316 ss LP2 Process Cover, Hastelloy C Sensor, Fluorinert Fill Fluid |

57 |

| F1 |

= |

Prepared For Foxboro Direct Connect Seal On High Side (Flanged PSFLT Or Sanitary PSSCT Or PSSST) & 1/2 NPT Connection on Low Side; Silicone Fill In Sensor |

F1 |

| F2 |

= |

Prepared For Foxboro Direct Connect Seal On High Side (Flanged PSFLT Or Sanitary PSSCT Or PSSST) & 1/2 NPT Connection on Low Side; Fluorinert Fill n Sensor |

F2 |

| F3 |

= |

Prepared For Foxboro Direct Connect Seal On High Side (Flanged PSFLT Or Sanitary PSSCT Or PSSST) & Remote Seal On Low Side; Silicone Fill In Sensor |

F3 |

| F4 |

= |

Prepared For Foxboro Direct Connect Seal On High Side (Flanged PSFLT Or Sanitary PSSCT Or PSSST) & Remote Seal On Low Side; Fluorinert Fill In Sensor |

F4 |

| S1 |

= |

Prepared For Foxboro Remote Seal On High & Low Sides; Silicone Fill In Sensor |

S1 |

| S2 |

= |

Prepared For Foxboro Remote Seal, High & Low Sides; Fluorinert In Sensor |

S2 |

| S3 |

= |

Prepared For Foxboro Remote Seal On High Side & 1/2 NPT Connection On Low Side; Silicone Fill In Sensor |

S3 |

| S4 |

= |

Prepared For Foxboro Remote Seal On High Side & 1/2 NPT Connection On Low Side; Fluorinert Fill In Sensor |

S4 |

| S5 |

= |

Prepared For Foxboro Remote Seal On Low Side & 1/2 NPT Connection On High Side; Silicone Fill In Sensor |

S5 |

| S6 |

= |

Prepared For Foxboro Remote Seal On Low Side & 1/2 NPT Connection On High Side; Fluorinert Fill In Sensor |

S6 |

| SA |

= |

Prepared For Other Remote Seals On High & Low Sides; Silicone Fill In Sensor |

SA |

| SB |

= |

Prepared For Other Remote Seals On High & Low Sides; Fluorinert Fill In Sensor |

SB |

| SC |

= |

Prepared For Other Remote Seal On High Side & 1/2 NPT Connection on Low Side; Silicone Fill In Sensor |

SC |

| SD |

= |

Prepared For Other Remote Seal On High Side & 1/2 NPT Connection on Low Side; Fluorinert Fill In Sensor |

SD |

| SE |

= |

Prepared For Other Remote Seal On Low Side & 1/2 NPT Connection on High Side; Silicone Fill In Sensor |

SE |

| SF |

= |

Prepared For Other Remote Seal On Low Side & 1/2 NPT Connection on High Side; Fluorinert Fill In Sensor |

SF |

| SPAN LIMITS: |

|

| A |

= |

0.12 And 7.5 kPa, 0.5 And 30 inH2O, 1.2 And 75 mbar |

A |

| B |

= |

0.87 And 50 kPa, 3.5 And 200 inH2O, 8.7 And 500 mbar |

B |

| C |

= |

7 And 210 kPa, 28 And 840 inH2O, 70 And 2100 mbar |

C |

| D |

= |

0.07 And 2.1 MPa, 10 And 300 psi, 0.7 And 21 bar |

D |

| E |

= |

0.7 And 21 MPa, 100 And 3000 psi, 7.0 And 210 bar |

E |

| PROCESS CONNECTOR: (Matl Same As Process Cover) |

|

| 0 |

= |

No Connectors, Both Covers Tapped For 1/4 NPT |

0 |

|

|

|

WITH (Structure Code:10, 11, 12, 13, 16, 17, 20, 21, 22, 23, 2G, 24, 25, 26, 27, 34, 35, 46, 47, 48, 49, 52, 53, 56, 57, LL, LM, LC, LD) |

|

|

|

1/2 NPT 316 ss, Process Connector On Low Side |

|

|

|

No Connectors, Both Sides Prepared For Seals |

|

|

|

No Connectors, Both Covers Tapped For Capillary Connections |

|

|

|

1/2 NPT 316 ss Process Connector On Side Opposite Seal |

| 1 |

= |

1/4 NPT |

1 |

|

|

|

WITH (Structure Code:10, 11, 12, 13, 16, 17, 20, 21, 22, 23, 2G, 24, 25, 26, 27, 52, 53, 56, 57, LL, LM, LC, LD) |

|

|

|

WITH (Structure Code:34, 35) |

| 2 |

= |

1/2 NPT |

2 |

|

|

|

WITH (Structure Code:10, 11, 12, 13, 16, 17, 20, 21, 22, 23, 2G, 24, 25, 26, 27, 52, 53, 56, 57, LL, LM, LC, LD) |

|

|

|

WITH (Structure Code:34, 35, 46, 47, 48, 49) |

| 3 |

= |

Rc 1/4 |

3 |

|

|

|

WITH (Structure Code:10, 11, 12, 13, 16, 17, 20, 21, 22, 23, 2G, 24, 25, 26, 27, 52, 53, 56, 57, LL, LM, LC, LD) |

|

|

|

WITH (Structure Code:34, 35) |

| 4 |

= |

Rc 1/2 |

4 |

|

|

|

WITH (Structure Code:10, 11, 12, 13, 16, 17, 20, 21, 22, 23, 2G, 24, 25, 26, 27, 52, 53, 56, 57, LL, LM, LC, LD) |

|

|

|

WITH (Structure Code:34, 35, 46, 46, 48, 49) |

| 6 |

= |

1/2 Schedule 80 Welding Neck |

6 |

|

|

|

WITH (Structure Code:10, 11, 12, 13, 16, 17, 20, 21, 22, 23, 2G, 24, 25, 26, 27, 52, 53, 56, 57, LL, LM, LC, LD) |

|

|

|

WITH (Structure Code:34, 35) |

| 7 |

= |

None, pvdf (Kynar) Insert Tapped For 1/2 NPT On Side Of 316 ss Process Covers |

7 |

| CONDUIT CONNECTION & HOUSING MATERIAL: |

|

| 1 |

= |

1/2 NPT Conduit Connection, Both Sides, Aluminum Housing |

1 |

| 2 |

= |

PG13.5 Conduit Connection, Both Sides, Aluminum Housing |

2 |

| 3 |

= |

1/2 NPT Conduit Connection, Both Sides, 316 ss Housing |

3 |

| 4 |

= |

PG13.5 Conduit Connection, Both Sides, 316 ss Housing |

4 |

| 5 |

= |

M20 Conduit Connection, Both Sides, Aluminum Housing |

5 |

| 6 |

= |

M20 Conduit Connection, Both Sides, 316 ss Housing |

6 |

| ELECTRICAL SAFETY: |

|

| E |

= |

ATEX Intrinsically Safe; II 1 GD, EEx ia IIC, Zone 0 |

E |

|

|

|

WITH (Electronics Version And Output Signal:D, T) |

|

|

|

ATEX FISCO Intrinsically Safe; II 1 GD, EEx ia IIC, Zone 0 |

| D |

= |

ATEX Flameproof; II 2 GD EEx d IIC, Zone 1 |

D |

| N |

= |

ATEX Protection n; II 3 GD, EEx nL IIC, Zone 2 |

N |

|

|

|

WITH (Electronics Version And Output Signal:T, D) |

|

|

|

ATEX FNICO Protection n; II 3 GD, EEx nL IIC, Zone 2 |

| M |

= |

Multiple ATEX Certifications - ATEX Intrinsically Safe; II 1 GD, EEx ia IIC, Zone 0; Or II 1/2 GD EEx ib IIC, Zone 0 / Zone 1; Or ATEX Protection n, II 3 GD, EEx nL IIC, Zone 2; Or ATEX Flameproof, II 2 GD EEx d IIC, Zone 1. The User Is Required to Permanently Mark In A Box On The Data Plate One Type Of Protection Only (ia & ib, d, or n) And Not Change This Mark. |

M |

| C |

= |

CSA Intrinsically Safe For Class I, Division 1, Groups A, B, C, & D; Class II, Division 1, Groups E,F, & G; And Class III, Division 1. Also Class I, Division 2, Groups A,B,C, & D; Class II, Groups F & G; And Class III, Division 2. Explosionproof For Class I, Division 1, Groups B,C, & D; Dust-Ignitionproof For Class II, Division 1, Groups E,F,G; And Class III, Div 1. Zone Certified Intrinsically Safe Ex ia IIC And Ex n IIC. Dual Seal Certification per ANSI/ISA 12.27.01.2003. |

C |

|

|

|

WITH (Electronics Version And Output Signal:T, V) |

|

|

|

CSA Intrinsically Safe For Class I, Division 1, Groups A, B, C, & D; Class II, Division 1, Groups E,F, & G; And Class III, Division 1. Also Class I, Division 2, Groups A,B,C, & D; Class II, Groups F & G; And Class III, Division 2. Explosionproof For Class I, Division 1, Groups B,C, & D; Dust-Ignitionproof For Class II, Division 1, Groups E,F,G; And Class III, Div 1. Dual Seal Certification per ANSI/ISA 12.27.01.2003. |

|

|

|

CSA Explosionproof For Class I, Division 1, Groups B,C, & D; Dust-Ignitionproof For Class II, Division 1, Groups E,F,G; Class III, Division 1. Also Class I, Division 2, Groups A,B,C, & D; Class II, Division 2, Groups F & G; Class III, Division 2. Dual Seal Certification per ANSI/ISA 12.27.01.2003. |

|

|

|

CSA FISCO/FNICO Field Device Intrinsically Safe For Class I, Division 1, Groups A, B, C, & D; Class II, Division 1, Groups E,F, & G; And Class III, Division 1. Class I, Division 2, Groups A,B,C, & D; Class II, Groups F & G; And Class III, Division 2. Explosionproof For Class I, Division 1, Groups B,C, & D; Dust-Ignitionproof For Class II, Division 1, Groups E,F,G; And Class III, Div 1. Zone Certified Ex ia IIC And Ex n IIC. Dual Seal Certification per ANSI/ISA 12.27.01.2003. |

| B |

= |

CSA Zone Certified Flameproof Ex d IIC. Also Explosionproof For Class I, Division 1, Groups B,C & D And Dust-Ignitionproof For Class II, Division 1 Groups E,F & G, And Class III, Division 1. Also Intrinsically Safe For Class I, Division 1, Groups A,B,C & D; Class II, Division 1, Groups E,F & G; And Class III, Division 1 And Class I, Division 2, Groups A,B,C, & D; Class II, Groups F & G; And Class III, Division 2. Zone Certified Intrinsically Safe Ex ia IIC And Ex n IIC. Dual Seal Certification per ANSI/ISA 12.27.01.2003. |

B |

|

|

|

WITH (Electronics Version And Output Signal:T, V) |

|

|

|

CSA Zone Certified Flameproof Ex d IIC. Also Explosionproof For Class I, Division 1, Groups B,C & D And Dust-Ignitionproof For Class II, Division 1 Groups E,F & G, And Class III, Division 1. Also Intrinsically Safe For Class I, Division 1, Groups A,B,C & D; Class II, Division 1, Groups E,F & G; And Class III, Division 1 And Class I, Division 2, Groups A,B,C, & D; Class II, Groups F & G; And Class III, Division 2. Dual Seal Certification per ANSI/ISA 12.27.01.2003. |

|

|

|

CSA Zone Certified Flameproof Ex d IIC. Also Explosionproof For Class I, Division 1, Groups B,C & D And Dust-Ignitionproof For Class II, Division 1 Groups E,F & G, And Class III, Division 1. Also Class I, Division 2, Groups A,B,C & D; Class II, Division 2, Groups F & G; And Class III, Division 2. Dual Seal Certification per ANSI/ISA 12.27.01.2003. |

|

|

|

CSA FISCO/FNICO Field Device Zone Certified Ex ia IIC And Ex n IIC Intrinsically Safe And Zone Certified Flameproof Ex d IIC. Also Intrinsically Safe For Class I, Division 1, Groups A, B, C, & D; Class II, Division 1, Groups E,F, & G; And Class III, Division 1. Class I, Division 2, Groups A,B,C, & D; Class II, Groups F & G; And Class III, Division 2. Also Explosionproof For Class I, Division 1, Groups B,C, & D; Dust-Ignitionproof For Class II, Division 1, Groups E,F,G; And Class III, Div 1. Dual Seal Certification per ANSI/ISA 12.27.01.2003. |

| F |

= |

FM Intrinsically Safe For Class I, Division 1, Groups A, B, C, & D; Class II, Division 1, Groups E,F, & G; And Class III, Division 1. Also Class I, Division 2, Groups A,B,C, & D; Class II, Groups F & G; And Class III, Division 2. Explosionproof For Class I, Division 1, Groups B,C, & D; Dust-Ignitionproof For Class II, Division 1, Groups E,F,G; And Class III, Div 1. Zone Certified Intrinsically Safe AEx ia IIC And AEx n IIC. |

F |

|

|

|

WITH (Electronics Version And Output Signal:T, V) |

|

|

|

FM Intrinsically Safe For Class I, Division 1, Groups A, B, C, & D; Class II, Division 1, Groups E,F, & G; And Class III, Division 1. Also Class I, Division 2, Groups A,B,C, & D; Class II, Groups F & G; And Class III, Division 2. Explosionproof For Class I, Division 1, Groups B,C, & D; Dust-Ignitionproof For Class II, Division 1, Groups E,F,G; And Class III, Div 1. |

|

|

|

FM FISCO/FNICO Field Device Intrinsically Safe For Class I, Division 1, Groups A, B, C, & D; Class II, Division 1, Groups E,F, & G; And Class III, Division 1. Class I, Division 2, Groups A,B,C, & D; Class II, Groups F & G; And Class III, Division 2. Explosionproof For Class I, Division 1, Groups B,C, & D; Dust-Ignitionproof For Class II, Division 1, Groups E,F,G; And Class III, Div 1. Zone Certified AEx ia IIC And AEx n IIC. |

|

|

|

FM Explosionproof For Class I, Division 1, Groups B,C, & D; Dust-Ignitionproof For Class II, Division 1, Groups E,F,G; Class III, Division 1. Also Nonincendive For Class I, Division 2, Groups A,B,C, & D; Class II, Division 2, Groups F & G; Class III, Division 2. |

| G |

= |

FM Zone Certified Flameproof AEx d IIC. Also Explosionproof For Class I, Division 1, Groups B,C & D And Dust-Ignitionproof For Class II, Division 1 Groups E,F & G, And Class III, Division 1. Also Intrinsically Safe For Class I, Division 1, Groups A,B,C & D; Class II, Division 1, Groups E,F & G; And Class III, Division 1 And Class I, Division 2, Groups A,B,C, & D; Class II, Groups F & G; And Class III, Division 2. Zone Certified Intrinsically Safe AEx ia IIC And AEx n IIC. |

G |

|

|

|

WITH (Electronics Version And Output Signal:T, V) |

|

|

|

FM Zone Certified Flameproof AEx d IIC. Also Explosionproof For Class I, Division 1, Groups B,C & D And Dust-Ignitionproof For Class II, Division 1 Groups E,F & G, And Class III, Division 1. Also Intrinsically Safe For Class I, Division 1, Groups A,B,C & D; Class II, Division 1, Groups E,F & G; And Class III, Division 1 And Class I, Division 2, Groups A,B,C, & D; Class II, Groups F & G; And Class III, Division 2. |

|

|

|

FM Zone Certified Flameproof AEx d IIC. Also Explosionproof For Class I, Division 1, Groups B,C & D And Dust-Ignitionproof For Class II, Division 1 Groups E,F & G, And Class III, Division 1. Also Nonincendive For Class I, Division 2, Groups A,B,C & D; Class II, Division 2, Groups F & G; And Class III, Division 2. |

|

|

|

FM FISCO/FNICO Field Device Zone Certified AEx ia IIC And AEx n IIC Intrinsically Safe And Zone Certified Flameproof AEx d IIC. Also Intrinsically Safe For Class I, Division 1, Groups A, B, C, & D; Class II, Division 1, Groups E,F, & G; And Class III, Division 1. Class I, Division 2, Groups A,B,C, & D; Class II, Groups F & G; And Class III, Division 2. Also Explosionproof For Class I, Division 1, Groups B,C, & D; Dust-Ignitionproof For Class II, Division 1, Groups E,F,G; And Class III, Div 1. |

| T |

= |

IECEx Intrinsically Safe, FISCO Ex ia IIC T4 |

T |

|

|

|

WITH (Electronics Version And Output Signal:F) |

|

|

|

IECEx Intrinsically Safe, Ex ia IIC T4 |

| U |

= |

IECEx Intrinsically Safe, Protection n; FNICO Ex |

U |

|

|

|

WITH (Electronics Version And Output Signal:F) |

|

|

|

IECEx Intrinsically Safe, Protection n; Ex nL IIC T4 |

| V |

= |

IECEx Flameproof, Ex d IIC T6 |

V |

| W |

= |

Multi Mark (Intrinsic safe ONLY for FM, CSA & ATEX) |

W |

| OPTIONAL MODEL SUFFIX(ES) INCLUDED: (a) |

|

| M1 |

= |

Painted Steel Mounting Bracket With Plated Steel Bolts |

M1 |

| M2 |

= |

316 ss Bracket with 316 ss Bolts |

M2 |

| M3 |

= |

Universal 304 S.Steel Bracket With 304 S.S Bolts Steel Bolts |

M3 |

| L1 |

= |

Digital Indicator, Internal Pushbuttons, And Window Cover |

L1 |

|

|

|

WITH (Conduit Connection & Housing Material:1, 2, 5) |

|

|

|

WITH (Conduit Connection & Housing Material:3, 4, 6) |

| L2 |

= |

Blind (Solid) Cover Over Standard LCD |

L2 (d) |

| S2 |

= |

SIL2 Certification |

S2 |

| D1 |

= |

Single Ended Process Covers With Standard Steel M10 Bolting |

D1 (e) |

| D2 |

= |

Double Ended Process Covers With Standard Steel M10 Bolting (Blind Kidney Flanges On Back) |

D2 (f) |

| D3 |

= |

Single Ended Process Covers With Standard Steel 7/16-Inch Bolting |

D3 |

| D4 |

= |

Double Ended Process Covers With Standard Steel 7/16-Inch Bolting (Blind Kidney Flanges On Back) |

D4 (f) |

| D5 |

= |

Single Ended Process Covers With 316 ss 7/16-Inch Bolting |

D5 (g) |

| D6 |

= |

Double Ended Process Covers With 316 ss 7/16-Inch Bolting (Blind Kidney Flange On Back) |

D6 (f) |

| D7 |

= |

Single Ended Process Covers With 17-4 ss 7/16-Inch Bolting |

D7 |

| D8 |

= |

Double Ended Process Covers With 17-4 ss 7/16-Inch Bolting (Blind Kidney Flange On Back) |

D8 (f) |

| D9 |

= |

Single Ended Process Covers With 17-4 ss 7/16-Inch Bolting And 40 MPa (400 bar, 5800 psi) Static Pressure Rating |

D9 |

| X1 |

= |

Unit Degreased (Not For Oxygen/Chlorine Service) |

X1 |

| X2 |

= |

Cleaned And Prepared For Oxygen Service |

X2 |

| X3 |

= |

Cleaned And Prepared For Chlorine Service; Includes 17 - 4 ss Bolts & Nuts |

X3 |

| B1 |

= |

316 ss Bolts And Nuts For Process Covers/ Connectors |

B1 |

|

|

|

WITH (Process Connector:0) |

|

|

|

WITH (Process Connector:1, 2, 3, 4, 6) |

| B2 |

= |

17-4 ss Bolts And Nuts For Process Covers/ Connectors |

B2 |

|

|

|

WITH (Process Connector:0) |

|

|

|

WITH (Process Connector:1, 2, 3, 4, 6) |

| B3 |

= |

B7M Bolts And Nuts (NACE) |

B3 (h) |

|

|

|

WITH (Process Connector:0) |

|

|

|

WITH (Process Connector:1, 2, 3, 4, 6) |

| A1 |

= |

Hawke Type Cable Gland |

A1 |

| A2 |

= |

Plastic PG13.5 Connector |

A2 |

| A3 |

= |

M20 Connector |

A3 |

| A4 |

= |

Trumpet Shaped PG13.5 Cable Gland (Nickel Plated Brass) |

A4 |

| Z1 |

= |

External Zero Adjustment |

Z1 |

| Z2 |

= |

Custody Transfer Lock And Seal |

Z2 |

| Z3 |

= |

External Zero Adjustment And Custody Transfer Lock And Seal |

Z3 |

| E1 |

= |

Steel, Connecting 6 mm Tubing To 1/4 NPT Process Connector |

E1 |

| E2 |

= |

Steel, Connecting 12 mm Tubing To 1/2 NPT Process Connector |

E2 |

| E3 |

= |

316 ss, Connecting 6 mm Tubing To 1/4 NPT Process Connector |

E3 |

| E4 |

= |

316 ss, Connecting 12 mm Tubing To 1/2 NPT Process Connector |

E4 |

| C1 |

= |

Digital Output (4 To 20 mA Default If Not Selected) |

C1 |

| C2 |

= |

Full Factory Configuration (Requires Configuration Form) |

C2 |

| V |

= |

Supply Vent Screw In Side Of Each Process Cover |

V |

|

|

|

WITH (Structure Code:10, 11, 12, 13, 16, 17, 20, 21, 22, 23, 2G, 24, 25, 26, 27) |

|

|

|

WITH (Structure Code:34, 35) |

|

|

|

WITH (Structure Code:46, 47, 48, 49) |

| V1 |

= |

Omit Vent Screw In Side Of Each Process Cover |

V1 |

| P1 |

= |

Adapter Set For MC Coplanar Manifold, B7 Bolts |

P1 (i) |

| P2 |

= |

Adapter Set For MC Coplanar Manifold, 316 ss Bolts |

P2 (i) |

| P3 |

= |

Adapter Set For MC Coplanar Manifold, 17-4ss Bolts |

P3 (i) |

| P4 |

= |

Adapter Set For MC Coplanar Manifold, B7M Bolts |

P4 (i) |

| P5 |

= |

Adapter Set For MT3 Coplanar Manifold, Traditional Flange, B7 Bolts |

P5 (i) |

| P6 |

= |

Adapter Set For MT3 Coplanar Manifold, Traditional Flange, 316 ss Bolts |

P6 (i) |

| P7 |

= |

Adapter Set For MT3 Coplanar Manifold, Traditional Flange, 17-4 ss Bolts |

P7 (i) |

| P8 |

= |

Adapter Set For MT3 Coplanar Manifold, Traditional Flange, B7M Bolts |

P8 (i) |

| H1 |

= |

Manifold Attachment and Leak Tested |

H1 |

| H2 |

= |

Manifold Attachment and Pressure Certificatiion |

H2 |

| VA |

= |

Veris Accelabar Data Sheet |

VA (j) |

| VV |

= |

Veris Verabar Data Sheet |

VV (j) |

| K1 |

= |

Without Instruction Book & CD |

K1 (k) |

| G1 |

= |

Gasket For Vacuum Service With Seals |

G1 (l) |

| T |

= |

Supplemental Tag |

T |

| Y |

= |

5800 psi (400 bar or kg/cm², 40 MPa) Static Pressure Rating |

Y |

| J |

= |

Low Temperature Operative Limit Of -50°C (-58°F) |

J (m) |

| (a) Standard transmitter (no K option specified) includes a paper instruction manual and a full documentation set on a CD. |

| (b) WirelessHART Adaptors, Temperature Converters and Gateways can be ordered separately via part numbers 217233, 217234, 211735, 220390, 211734, 219035 and 211749 . |

| (c) Refer to TI 37-75b and 37-78 for information regarding the highly corrosion-resistant properties of cobalt-nickel-chrome (Co-Ni-Cr) sensor material. |

| (d) Electronics Version A & V have LCD and Window Cover as standard. Only specify -L2 option to substitute solid cover for standard window cover. |

| (e) Pressure limited to 2320 psi (160 bar). |

| (f) Mounting set option is not available and maximum working pressure is 1500 psi or 100 bar. Temperature limits are 32 & 140°F or 0 & 60°C. |

| (g) Maximum working pressure is 2175 psi or 150 bar. |

| (h) Normally requires selection of AS Reference MR-01 |

| (i) Refer to PSS for manifold compatibility. |

| (j) download at (http://iom.invensys.com/EN/Pages/Foxboro_MandI_DocTools.aspx) Complete and send to Veris for Engineering review |

| (k) Only a brief "Getting Started" document is supplied. |

| (l) Substitutes vacuum service metal gasket for standard ptfe process cover gasket. Required when seal will be used in vacuum applications. |

(m) If a 2-inch (50 mm) seal is required for -50°C service, contact Foxboro. Certain combinations of fill fluid and capillary length may be acceptable.

Vui lòng liên hệ với đại lý ủy quyền của Foxboro tại Việt Nam để được hỗ trợ: ☞ Foxboro Vietnam>> Vui lòng liên hệ với đại lý ủy quyền của Foxboro tại Việt Nam để được hỗ trợ: ☞ Foxboro Vietnam>> |

Vui lòng liên hệ với đại lý ủy quyền của Foxboro tại Việt Nam để được hỗ trợ: ☞ Foxboro Vietnam>>

Vui lòng liên hệ với đại lý ủy quyền của Foxboro tại Việt Nam để được hỗ trợ: ☞ Foxboro Vietnam>>

Đăng nhận xét Blogger Facebook