| | | Description | Model |

| IMV25 | = | Measures Differential Pressure And Absolute Pressure And Can Transmit These Measurements Along With Process Temperature. | IMV25 |

| ELECTRONICS VERSION AND OUTPUT SIGNAL: | |

| T | = | Digital HART & 4 To 20 mA | T |

| M | = | Digital Modbus | M |

| STRUCTURE CODE: | |

| 22 | = | 316 ss Process Cover, 316L ss Sensor, Silicone Fill Fluid | 22 |

| 23 | = | 316 ss Process Cover, 316L ss Sensor, Fluorinert Fill Fluid | 23 |

| 26 | = | 316 ss Process Cover, Hastelloy C Sensor, Silicone Fill Fluid | 26 |

| 27 | = | 316 ss Process Cover, Hastelloy C Sensor, Fluorinert Fill Fluid | 27 |

| 46 | = | Hastelloy C Process Cover, Hastelloy C Sensor, Silicone Fill Fluid | 46 |

| 47 | = | Hastelloy C Process Cover, Hastelloy C Sensor, Fluorinert Fill Fluid | 47 |

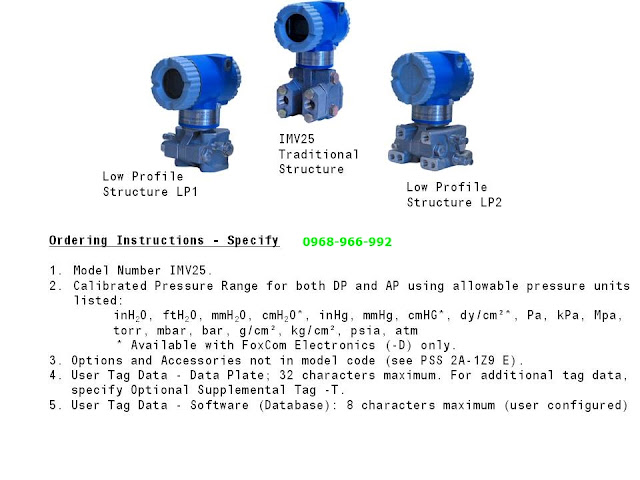

| LL | = | 316 ss LP1 Process Cover, 316L ss Sensor, Silicone Fill Fluid | LL |

| LM | = | 316 ss LP1 Process Cover, 316L ss Sensor, Fluorinert Fill Fluid | LM |

| LC | = | 316 ss LP1 Process Cover, Hastelloy C Sensor, Silicone Fill Fluid | LC |

| LD | = | 316 ss LP1 Process Cover, Hastelloy C Sensor, Fluorinert Fill Fluid | LD |

| 52 | = | 316 ss LP2 Process Cover, 316L ss Sensor, Silicone Fill Fluid | 52 |

| 53 | = | 316 ss LP2 Process Cover, 316L ss Sensor, Fluorinert Fill Fluid | 53 |

| 56 | = | 316 ss LP2 Process Cover, Hastelloy C Sensor, Silicone Fill Fluid | 56 |

| 57 | = | 316 ss LP2 Process Cover, Hastelloy C Sensor, Fluorinert Fill Fluid | 57 |

| DIFFERENTIAL PRESSURE SPAN LIMITS: | |

| L | = | 0.12 & 2.5 kPa, 0.5 & 10 inH2O, 1.2 & 25 mbar | L |

| A | = | 0.75 & 7.5 kPa, 3 & 30 inH2O, 7.5 & 75 mbar | A |

| B | = | 0.5 & 50 kPa, 2 & 200 inH2O, 5.0 & 500 mbar | B |

| G | = | 0.5 & 100 kPa, 2 & 400 inH2O, 5 & 1000 mbar | G |

| C | = | 2.5 & 210 kPa, 10 & 840 inH2O, 25 & 2100 mbar | C |

| ABSOLUTE PRESSURE SPAN LIMITS: | |

| D | = | 0.02 & 2.1 MPa, 3 & 300 psi, 0.21 & 21 bara or kg/cm² | D |

| G | = | 0.07 & 3.5 MPa, 10 & 500 psi, 0.7 & 35 bara or kg/cm² | G |

| E | = | 0.21 & 10 MPa, 30 & 1500 psi, 2.1 & 103 bara or kg/cm² | E |

| H | = | 0.42 & 20.7 MPa, 60 & 3000 psi, 4.2 & 207 bara or kg/cm² | H |

| F | = | 3.45 & 36.5 MPa, 500 & 5300 psi, 34.5 & 365 bar or kg/cm² | F |

| OTHER MEASUREMENTS: | |

| 1 | = | Temperature-Terminal Block Supports Connection Of External 100 ohm Platinum RTD | 1 |

| PROCESS CONNECTOR: (Matl Same As Process Cover) | |

| 0 | = | None, Covers Tapped For 1/4 NPT | 0 |

| 1 | = | 1/4 NPT | 1 |

| 2 | = | 1/2 NPT | 2 |

|

|

| WITH (Structure Code:22, 23, 26, 27, 52, 53, 56, 57, LL, LM, LC, LD) |

|

|

| WITH (Structure Code:46, 47) |

| 3 | = | Rc 1/4 | 3 |

| 4 | = | Rc 1/2 | 4 |

|

|

| WITH (Structure Code:22, 23, 26, 27, 52, 53, 56, 57, LL, LM, LC, LD) |

|

|

| WITH (Structure Code:46, 47) |

| 6 | = | Schedule 80 Welding Neck | 6 |

| CONDUIT CONNECTION & HOUSING MATERIAL: | |

| 1 | = | 1/2 NPT Conduit Connection, Aluminum Housing | 1 |

| 2 | = | PG13.5 Conduit Connection, Aluminum Housing | 2 |

| 3 | = | 1/2 NPT Conduit Connection, 316 ss Housing | 3 |

| 4 | = | PG13.5 Conduit Connection, 316 ss Housing | 4 |

| 5 | = | M20 Conduit Connection, Both Sides, Aluminum Housing | 5 |

| 6 | = | M20 Conduit Connection, Both Sides, 316 ss Housing | 6 |

| ELECTRICAL SAFETY: | |

| E | = | ATEX Intrinsically Safe; II 1 GD, EEx ia IIC, Zone 0: Or II 1/2 GD EEx ib IIC, Zone 0 / Zone 1 | E |

| D | = | ATEX Flameproof; II 2 GD EEx d IIC, Zone 1 | D |

| N | = | ATEX Protection n; II 3 GD, EEx nL IIC, Zone 2 | N |

| M | = | Multiple

ATEX Certifications - ATEX Intrinsically Safe; II 1 GD, EEx ia IIC,

Zone 0: Or II 1/2 GD EEx ib IIC, Zone 0 / Zone 1; Or ATEX Protection n;

II 3 GD, EEx nL IIC, Zone 2. The User Is Required to Permanently Mark In

A Box On The Data Plate One Type Of Protection Only (ia & ib, d, or

n) And Not Change This Mark. | M |

| C | = | CSA

Intrinsically Safe For Class I, Division 1, Groups A, B, C, & D;

Class II, Division 1, Groups E,F, & G; And Class III, Division 1.

Also Class I, Division 2, Groups A,B,C, & D; Class II, Groups F

& G; And Class III, Division 2. Explosionproof For Class I, Division

1, Groups B,C, & D; Dust-Ignitionproof For Class II, Division 1,

Groups E,F,G; And Class III, Div 1. Zone Certified Intrinsically Safe Ex

ia IIC And Ex n IIC. Dual Seal Certification per ANSI/ISA

12.27.01.2003. | C |

|

|

| WITH (Electronics Version And Output Signal:T) |

|

|

| CSA

Explosionproof For Class I, Division 1, Groups B,C, & D;

Dust-Ignitionproof For Class II, Division 1, Groups E,F,G; Class III,

Division 1. Dual Seal Certification per ANSI/ISA 12.27.01.2003. |

| B | = | CSA

Zone Certified Flameproof Ex d IIC. Also Explosionproof For Class I,

Division 1, Groups B,C & D And Dust-Ignitionproof For Class II,

Division 1 Groups E,F & G, And Class III, Division 1. Also

Intrinsically Safe For Class I, Division 1, Groups A,B,C & D; Class

II, Division 1, Groups E,F & G; And Class III, Division 1 And Class

I, Division 2, Groups A,B,C & D; Class II Groups F & G; And

Class III, Division 2. Zone Certified Intrinsically Safe Ex ia IIC And

Ex n IIC. Dual Seal Certification per ANSI/ISA 12.27.01.2003. | B |

|

|

| WITH (Electronics Version And Output Signal:T) |

|

|

| CSA

Zone Certified Flameproof Ex d IIC. Also Explosionproof For Class I,

Division 1, Groups B,C & D And Dust-Ignitionproof For Class II,

Division 1 Groups E,F & G, And Class III, Division 1. Dual Seal

Certification per ANSI/ISA 12.27.01.2003. |

| F | = | FM

Intrinsically Safe For Class I, Division 1, Groups A, B, C, & D;

Class II, Division 1, Groups E,F, & G; And Class III, Division 1.

Also Class I, Division 2, Groups A,B,C, & D; Class II, Groups F

& G; And Class III, Division 2. Explosionproof For Class I, Division

1, Groups B,C, & D; Dust-Ignitionproof For Class II, Division 1,

Groups E,F,G; And Class III, Div 1. Zone Certified Intrinsically Safe

AEx ia IIC And AEx n IIC. | F (b) |

|

|

| WITH (Electronics Version And Output Signal:T) |

|

|

| FM

Explosionproof For Class I, Division 1, Groups B,C, & D;

Dust-Ignitionproof For Class II, Division 1, Groups E,F,G; Class III,

Division 1. |

| G | = | FM

Zone Certified Flameproof AEx d IIC. Also Explosionproof For Class I,

Division 1, Groups B,C & D And Dust-Ignitionproof For Class II,

Division 1 Groups E,F & G, And Class III, Division 1. Also

Intrinsically Safe For Class I, Division 1, Groups A,B,C & D; Class

II, Division 1, Groups E,F & G; And Class III, Division 1 And Class

I, Division 2, Groups A,B,C, & D; Class II, Groups F & G; And

Class III, Division 2. Zone Certified Intrinsically Safe AEx ia IIC And

AEx n IIC. | G |

|

|

| WITH (Electronics Version And Output Signal:T) |

|

|

| FM

Zone Certified Flameproof AEx d IIC. Also Explosionproof For Class I,

Division 1, Groups B,C & D And Dust-Ignitionproof For Class II,

Division 1 Groups E,F & G, And Class III, Division 1. |

| V | = | IECEx Flameproof Ex d IIC T6 | V |

| OPTIONAL MODEL SUFFIX(ES) INCLUDED: (a) | |

| M1 | = | Painted Steel Mounting Bracket Set With Plated Steel Bolts | M1 |

| M2 | = | 316 ss Bracket with 316 ss Bolts | M2 |

| M3 | = | Universal 304 S.Steel Bracket With 304 S.S Bolts With Stainless Steel Bolts | M3 |

| D1 | = | Single Ended Process Covers With Standard Steel M10 Bolting | D1 (c) |

| D2 | = | Double Ended Process Covers With Standard Steel M10 Bolting (Blind Kidney Flanges On Back) | D2 (c) |

| D3 | = | Single Ended Process Covers With Standard Steel 7/16-Inch Bolting | D3 |

| D4 | = | Double Ended Process Covers With Standard Steel 7/16-Inch Bolting (Blind Kidney Flanges On Back) | D4 (c) |

| D5 | = | Single Ended Process Covers With 316 ss 7/16-Inch Bolting | D5 (c) |

| D6 | = | Double Ended Process Covers With 316 ss 7/16-Inch Bolting (Blind Kidney Flange On Back) | D6 (c) |

| D7 | = | Single Ended Process Covers With 17-4 ss 7/16-Inch Bolting | D7 |

| D8 | = | Double Ended Process Covers With 17-4 ss 7/16-Inch Bolting (Blind Kidney Flange On Back) | D8 (c) |

| X1 | = | Unit Degreased (Not For Oxygen/Chlorine Service) | X1 |

| X2 | = | Cleaned And Prepared For Oxygen Service | X2 |

| X3 | = | Cleaned And Prepared For Chlorine Service | X3 |

| B1 | = | 316 ss Bolts And Nuts For Process Covers/ Connectors | B1 |

|

|

| WITH (Process Connector:0) |

|

|

| WITH (Process Connector:1, 2, 3, 4, 6) |

| B2 | = | 17-4 ss Bolts And Nuts For Process Covers/ Connectors | B2 |

|

|

| WITH (Process Connector:0) |

|

|

| WITH (Process Connector:1, 2, 3, 4, 6) |

| B3 | = | B7M Bolts And Nuts (NACE) | B3 (d) |

|

|

| WITH (Process Connector:0) |

|

|

| WITH (Process Connector:1, 2, 3, 4, 6) |

| A1 | = | Hawke Type Cable Gland | A1 |

| A3 | = | M20 Connector | A3 |

| E3 | = | Ermeto Connector - 316 ss, Connecting 6 mm Tubing To 1/4 NPT Process Connector | E3 |

| E4 | = | Ermeto Connector - 316 ss, Connecting 12 mm Tubing To 1/2 NPT Process Connector | E4 |

| C1 | = | Digital Output (4 To 20 mA Default If Not Selected) | C1 |

| C2 | = | Factory Configuration (Requires Configuration Form) | C2 |

| V | = | Supply Vent Screw In Side Of Each Process Cover | V |

|

|

| WITH (Structure Code:22, 23, 26, 27) |

|

|

| WITH (Structure Code:46, 47) |

| V1 | = | Omit Vent Screw In Side Of Each Process Cover | V1 |

| P1 | = | Adapter Set For MC Coplanar Manifold, B7 Bolts | P1 (e) |

| P2 | = | Adapter Set For MC Coplanar Manifold, 316 ss Bolts | P2 (e) |

| P3 | = | Adapter Set For MC Coplanar Manifold, 17-4ss Bolts | P3 (e) |

| P4 | = | Adapter Set For MC Coplanar Manifold, B7M Bolts | P4 (e) |

| P5 | = | Adapter Set For MT3 Coplanar Manifold, Traditional Flange, B7 Bolts | P5 (e) |

| P6 | = | Adapter Set For MT3 Coplanar Manifold, Traditional Flange, 316 ss Bolts | P6 (e) |

| P7 | = | Adapter Set For MT3 Coplanar Manifold, Traditional Flange, 17-4 ss Bolts | P7 (e) |

| P8 | = | Adapter Set For MT3 Coplanar Manifold, Traditional Flange, B7M Bolts | P8 (e) |

| H1 | = | Manifold Attachment and Leak Tested | H1 |

| H2 | = | Manifold Attachment and Pressure Certificatiion | H2 |

| L1 | = | Digital Indicator, Internal Pushbuttons, And Window Cover | L1 |

|

|

| WITH (Conduit Connection & Housing Material:1, 2, 5) |

|

|

| WITH (Conduit Connection & Housing Material:3, 4, 6) |

| Z2 | = | Custody Transfer Lock And Seal | Z2 |

| K1 | = | Without Instruction Book | K1 |

| T | = | Supplemental Tag | T |

| J | = | Low Temperature Operative Limit Of -50°C (-58°F) | J |

| (a) Standard transmitter (no K option specified) includes a paper instruction manual and a full documentation set on a CD. |

| (b) Includes Explosionproof, Division 2, and Intrinsic Safety for HART (-T) version; Explosionproof only for FoxCom (-D) version. |

| (c) Refer to PSS for derated pressure values with Span Code E. |

| (d) Normally requires selection of AS Reference MR-01 |

| (e) Refer to PSS for manifold compatibility. |

Đăng nhận xét Blogger Facebook