|

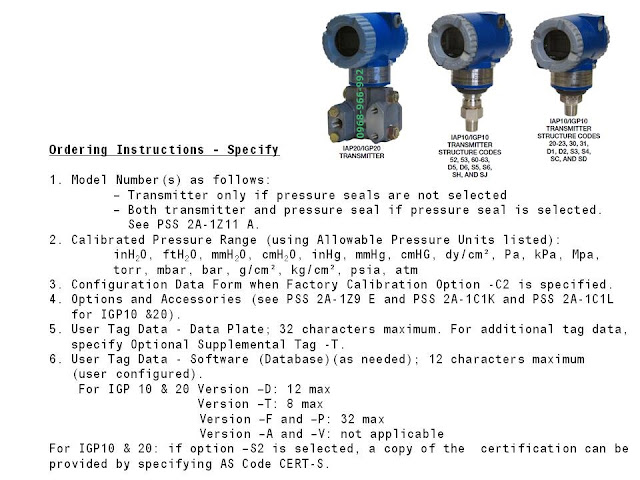

| Cảm biến áp suất Invensys Foxboro IAP10 |

Hướng dẫn lựa chọn cảm biến đo áp suất tuyệt đối Foxboro IAP10 của hãng Invensys

Description

|

|||

IAP10

|

=

|

Measures

Pressure And Transmits A Proportional Electrical Signal.

|

|

ELECTRONIC VERSION AND OUTPUT SIGNAL:

|

|||

D

|

=

|

Intelligent;

Digital FoxCom Or 4 To 20 mA, Configurable

|

|

T

|

=

|

Intelligent;

Digital HART & 4 To 20 mA

|

|

F

|

=

|

Intelligent;

FOUNDATION Fieldbus

|

|

A

|

=

|

4 To 20

mA; Includes Explosionproof Rating And LCD Indicator With Pushbuttons For

Calibration, Configuration, Standard Pressure Units, And Rearranging

(Excludes Custom Labels And Intrinsic Safety Rating)

|

|

V

|

=

|

Voltage

Output, 1 To 5 Vdc, Low Power, Including LCD Indicator With Pushbuttons

|

|

STRUCTURE CODE MATERIALS AND TYPE:

|

|||

20

|

=

|

316L ss

Process Connection, Co-Ni-Cr Diaphragm, Silicone Fill Fluid, 1/2 NPT External

& 1/4 NPT Internal Thread Connection Type

|

|

21

|

=

|

316L ss

Process Connection, Co-Ni-Cr Diaphragm, Fluorinert Fill Fluid, 1/2 NPT

External & 1/4 NPT Internal Thread Connection Type

|

|

22

|

=

|

316L ss

Process Connection, 316L ss Diaphragm, Silicone Fill Fluid, 1/2 NPT External

& 1/4 NPT Internal Thread Connection Type

|

|

23

|

=

|

316L ss

Process Connection, 316L ss Diaphragm, Fluorinert Fill Fluid, 1/2 NPT

External & 1/4 NPT Internal Thread Connection Type

|

|

30

|

=

|

316L ss

Process Connection, Hastelloy C Diaphragm, Silicone Fill Fluid, 1/2 NPT

External & 1/4 NPT Internal Thread Connection Type

|

|

31

|

=

|

316L ss

Process Connection, Hastelloy C Diaphragm, Fluorinert Fill Fluid, 1/2 NPT

External & 1/4 NPT Internal Thread Connection Type

|

|

52

|

=

|

316L ss

Process Connection, 316L ss Diaphragm, Silicone Fill Fluid, 1/2 NPT External

& 1/4 NPT Internal Thread Connection Type, Flameproof Certification

|

|

53

|

=

|

316L ss

Process Connection, 316L ss Diaphragm, Fluorinert Fill Fluid, 1/2 NPT

External & 1/4 NPT Internal Thread Connection Type, Flameproof

Certification

|

|

60

|

=

|

316L ss

Process Connection, Hastelloy C Diaphragm, Silicone Fill Fluid, 1/2 NPT

External & 1/4 NPT Internal Thread Connection Type, Flameproof

Certification

|

|

61

|

=

|

316L ss

Process Connection, Hastelloy C Diaphragm, Fluorinert Fill Fluid, 1/2 NPT

External & 1/4 NPT Internal Thread Connection Type, Flameproof

Certification

|

|

62

|

=

|

Hastelloy

C Process Connection, Hastelloy C Diaphragm, Silicone Fill Fluid, 1/2 NPT

External & 1/4 NPT Internal Thread Connection Type, Flameproof

Certification

|

|

63

|

=

|

Hastelloy

C Process Connection, Hastelloy C Diaphragm, Fluorinert Fill Fluid, 1/2 NPT

External & 1/4 NPT Internal Thread Connection Type, Flameproof

Certification

|

|

TA

|

=

|

316L ss

Process Connection, 316L ss Diaphragm, Neobee Fill Fluid, 1.5 Inch Tri-Clamp

Connection Type, With Sanitary Process Connections

|

|

T2

|

=

|

316L ss

Process Connection, 316L ss Diaphragm, Neobee Fill Fluid, 2.0 Inch Tri-Clamp

Connection Type, With Sanitary Process Connections

|

|

T3

|

=

|

316L ss

Process Connection, 316L ss Diaphragm, Neobee Fill Fluid, 3.0 Inch Tri-Clamp

Connection Type, With Sanitary Process Connections

|

|

TB

|

=

|

316L ss

Process Connection, Hastelloy C Diaphragm, Neobee Fill Fluid, 1.5 Inch

Tri-Clamp Connection Type, With Sanitary Process Connections

|

|

T4

|

=

|

316L ss

Process Connection, Hastelloy C Diaphragm, Neobee Fill Fluid, 2.0 Inch

Tri-Clamp Connection Type, With Sanitary Process Connections

|

|

T5

|

=

|

316L ss

Process Connection, Hastelloy C Diaphragm, Neobee Fill Fluid, 3.0 Inch

Tri-Clamp Connection Type, With Sanitary Process Connections

|

|

M1

|

=

|

316L ss

Process Connection, 316L ss Diaphragm, Neobee Fill Fluid, Mini Tank Spud Type

1 Inch External Connection Type, With Sanitary Process Connections

|

|

M6

|

=

|

316L ss

Process Connection, 316L ss Diaphragm, Neobee Fill Fluid, Mini Tank Spud Type

6 Inch External Connection Type, With Sanitary Process Connections

|

|

M9

|

=

|

316L ss

Process Connection, 316L ss Diaphragm, Neobee Fill Fluid, Mini Tank Spud Type

9 Inch External Connection Type, With Sanitary Process Connections

|

|

PA

|

=

|

316L ss

Process Connection, 316L ss Diaphragm, Silicone Fill Fluid, Sleeve Type 1

Inch (Nominal) Connection Type, With Pulp & Paper Process Connections

|

|

PB

|

=

|

316L ss

Process Connection, 316L ss Diaphragm, Silicone Fill Fluid, Threaded Type 1

Inch (Nominal) Connection Type, With Pulp & Paper Process Connections

|

|

PC

|

=

|

316L ss

Process Connection, 316L ss Diaphragm, Silicone Fill Fluid, Sleeve Type 1.5

Inch (Nominal) Connection Type, With Pulp & Paper Process Connections

|

|

PD

|

=

|

316L ss

Process Connection, 316L ss Diaphragm, Silicone Fill Fluid, Threaded Type 1.5

Inch (Nominal) Connection Type, With Pulp & Paper Process Connections

|

|

PE

|

=

|

316L ss

Process Connection, Hastelloy C Diaphragm, Silicone Fill Fluid, Sleeve Type 1

Inch (Nominal) Connection Type, With Pulp & Paper Process Connections

|

|

PF

|

=

|

316L ss

Process Connection, Hastelloy C Diaphragm, Silicone Fill Fluid, Threaded Type

1 Inch (Nominal) Connection Type, With Pulp & Paper Process Connections

|

|

PG

|

=

|

316L ss

Process Connection, Hastelloy C Diaphragm, Silicone Fill Fluid, Sleeve Type 1.5

Inch (Nominal) Connection Type, With Pulp & Paper Process Connections

|

|

PH

|

=

|

316L ss

Process Connection, Hastelloy C Diaphragm, Silicone Fill Fluid, Threaded Type

1.5 Inch (Nominal) Connection Type, With Pulp & Paper Process Connections

|

|

PJ

|

=

|

316L ss

Process Connection, Hastelloy C Diaphragm, Silicone Fill Fluid, Threaded Type

1.5 Inch To Fit Ametek Spud Connection Type, With Pulp & Paper Process

Connections

|

|

D1

|

=

|

Prepared

For Foxboro Direct Connect Seal; Silicone Fill In Sensor

|

|

D5

|

=

|

Prepared

For Foxboro Direct Connect Seal; Silicone Fill In Sensor, Flameproof

Certification

|

|

S3

|

=

|

Prepared

For Foxboro Remote Seal; Silicone Fill In Sensor

|

|

S5

|

=

|

Prepared

For Foxboro Remote Seal; Silicone Fill In Sensor, Flameproof Certification

|

|

SC

|

=

|

Silicone

Fill In Sensor; Prepared For Other Seals

|

|

SD

|

=

|

Fluorinert

Fill In Sensor; Prepared For Other Seals

|

|

SH

|

=

|

Silicone

Fill In Sensor, Flameproof Certification; Prepared For Other Seals

|

|

SJ

|

=

|

Fluorinert

Fill In Sensor, Flameproof Certification; Prepared For Other Seals

|

|

SPAN LIMITS:

|

|||

C

|

=

|

0.007 And

0.21 MPa, 1 And 30 psi, 0.07 And 2.1 bar or kg/cm²

|

|

D

|

=

|

0.07 And

2.1 MPa, 10 And 300 psi, 0.70 And 21 bar or kg/cm²

|

|

E

|

=

|

0.70 And

22 MPa, 100 And 3000 psi, 7.0 And 210 bar or kg/cm²

|

|

CONDUIT CONNECTION & HOUSING MATERIAL:

|

|||

1

|

=

|

1/2 NPT

Conduit Connection, Both Sides, Aluminum Housing

|

|

2

|

=

|

PG13.5

Conduit Connection, Both Sides, Aluminum Housing

|

|

3

|

=

|

1/2 NPT

Conduit Connection, Both Sides, 316 ss Housing

|

|

4

|

=

|

PG13.5

Conduit Connection, Both Sides, 316 ss Housing

|

|

5

|

=

|

M20

Conduit Connection, Both Sides, Aluminum Housing

|

|

6

|

=

|

M20

Conduit Connection, Both Sides, 316 ss Housing

|

|

ELECTRICAL SAFETY:

|

|||

E

|

=

|

ATEX

Intrinsically Safe; II 1 GD, EEx ia IIC, Zone 0

|

|

WITH

(Electronic Version And Output Signal:D, T)

|

|||

ATEX FISCO

Intrinsically Safe; II 1 GD, EEx ia IIC, Zone 0

|

|||

D

|

=

|

ATEX

Flameproof; II 2 GD EEx d IIC, Zone 1

|

|

N

|

=

|

ATEX

Protection n; II 3 GD, EEx nL IIC, Zone 2

|

|

WITH

(Electronic Version And Output Signal:T, D)

|

|||

ATEX FNICO

Protection n; II 3 GD, EEx nL IIC, Zone 2

|

|||

M

|

=

|

Multiple

ATEX Certifications - ATEX Intrinsically Safe; II 1 GD, EEx ia IIC, Zone 0:

Or II 1/2 GD EEx ib IIC, Zone 0 / Zone 1; Or ATEX Protection n; II 3 GD, EEx

nL IIC, Zone 2. The User Is Required to Permanently Mark In A Box On The Data

Plate One Type Of Protection Only (ia & ib, d, or n) And Not Change This

Mark.

|

|

P

|

=

|

Multiple

ATEX Certifications (Including Flameproof Zones) - ATEX Flameproof; II 2 GD

EEx d IIC, Zone 1; Or ATEX Intrinsically Safe; II 1 GD, EEx ia IIC, Zone 0:

Or II 1/2 GD EEx ib IIC, Zone 0 / Zone 1; Or ATEX Protection n; II 3 GD, EEx

nL IIC, Zone 2. The User Is Required to Permanently Mark In A Box On The Data

Plate One Type Of Protection Only (ia & ib, d, or n) And Not Change This

Mark.

|

|

C

|

=

|

CSA

Intrinsically Safe For Class I, Division 1, Groups A, B, C, & D; Class

II, Division 1, Groups E, F, & G; And Class III, Division 1. Also Class

I, Division 2, Groups A,B,C, & D; Class II, Groups F & G; And Class

III, Division 2. Explosionproof For Class I, Division 1, Groups B,C, & D;

Dust-Ignitionproof For Class II, Division 1, Groups E,F,G; And Class III, Div

1. Zone Certified Intrinsically Safe Ex ia IIC And Ex n IIC. Dual Seal

Certification per ANSI/ISA 12.27.01.2003.

|

|

WITH

(Electronic Version And Output Signal:T, V)

|

|||

CSA

Intrinsically Safe For Class I, Division 1, Groups A, B, C, & D; Class

II, Division 1, Groups E, F, & G; And Class III, Division 1. Also Class

I, Division 2, Groups A,B,C, & D; Class II, Groups F & G; And Class

III, Division 2. Explosionproof For Class I, Division 1, Groups B,C, & D;

Dust-Ignitionproof For Class II, Division 1, Groups E,F,G; And Class III, Div

1. Dual Seal Certification per ANSI/ISA 12.27.01.2003.

|

|||

CSA

FISCO/FNICO Field Device Intrinsically Safe For Class I, Division 1, Groups

A, B, C, & D; Class II, Division 1, Groups E,F, & G; And Class III,

Division 1. Class I, Division 2, Groups A,B,C, & D; Class II, Groups F

& G; And Class III, Division 2. Explosionproof For Class I, Division 1,

Groups B,C, & D; Dust-Ignitionproof For Class II, Division 1, Groups

E,F,G; And Class III, Div 1. Zone Certified Ex ia IIC And Ex n IIC. Dual Seal

Certification per ANSI/ISA 12.27.01.2003.

|

|||

CSA

Explosionproof For Class I, Division 1, Groups B,C, & D;

Dust-Ignitionproof For Class II, Division 1, Groups E,F,G; Class III,

Division 1. Also Class I, Division 2, Groups A,B,C, & D; Class II,

Division 2, Groups F & G; Class III, Division 2. Dual Seal Certification

per ANSI/ISA 12.27.01.2003.

|

|||

B

|

=

|

CSA Zone

Certified Flameproof Ex d IIC. Also Explosionproof For Class I, Division 1,

Groups B,C & D And Dust-Ignitionproof For Class II, Division 1 Groups E,F

& G, And Class III, Division 1. Also Intrinsically Safe For Class I,

Division 1, Groups A,B,C & D; Class II, Division 1, Groups E,F & G;

And Class III, Division 1 And Class I, Division 2, Groups A,B,C, & D;

Class II, Groups F & G; And Class III, Division 2. Zone Certified Intrinsically

Safe Ex ia IIC And Ex n IIC. Dual Seal Certification per ANSI/ISA

12.27.01.2003.

|

|

WITH

(Electronic Version And Output Signal:T, V) And (Structure Code Materials And

Type:52, 53, 60, 61, 62, 63, D5, S5, SH, SJ) And (Conduit Connection &

Housing Material:1, 3)

|

|||

CSA Zone

Certified Flameproof Ex d IIC. Also Explosionproof For Class I, Division 1,

Groups B,C & D And Dust-Ignitionproof For Class II, Division 1 Groups E,F

& G, And Class III, Division 1. Also Intrinsically Safe For Class I,

Division 1, Groups A,B,C & D; Class II, Division 1, Groups E,F & G;

And Class III, Division 1 And Class I, Division 2, Groups A,B,C, & D;

Class II, Groups F & G; And Class III, Division 2. Dual Seal

Certification per ANSI/ISA 12.27.01.2003.

|

|||

CSA Zone

Certified Flameproof Ex d IIC. Also Explosionproof For Class I, Division 1,

Groups B,C & D And Dust-Ignitionproof For Class II, Division 1 Groups E,F

& G, And Class III, Division 1. Also Class I, Division 2, Groups A,B,C

& D; Class II, Division 2, Groups F & G; And Class III, Division 2.

Dual Seal Certification per ANSI/ISA 12.27.01.2003.

|

|||

CSA

FISCO/FNICO Field Device Zone Certified Ex ia IIC And Ex n IIC Intrinsically

SAfe And Zone Certified Flameproof Ex d IIC. Also Intrinsically Safe For

Class I, Division 1, Groups A, B, C, & D; Class II, Division 1, Groups

E,F, & G; And Class III, Division 1. Class I, Division 2, Groups A,B,C,

& D; Class II, Groups F & G; And Class III, Division 2. Also

Explosionproof For Class I, Division 1, Groups B,C, & D;

Dust-Ignitionproof For Class II, Division 1, Groups E,F,G; And Class III, Div

1. Dual Seal Certification per ANSI/ISA 12.27.01.2003.

|

|||

F

|

=

|

FM

Intrinsically Safe For Class I, Division 1, Groups A, B, C, & D; Class

II, Division 1, Groups E,F, & G; And Class III, Division 1. Also Class I,

Division 2, Groups A,B,C, & D; Class II, Groups F & G; And Class III,

Division 2. Explosionproof For Class I, Division 1, Groups B,C, & D;

Dust-Ignitionproof For Class II, Division 1, Groups E,F,G; And Class III, Div

1. Zone Certified Intrinsically Safe AEx ia IIC And AEx n IIC.

|

|

WITH

(Electronic Version And Output Signal:T, V)

|

|||

FM

Intrinsically Safe For Class I, Division 1, Groups A, B, C, & D; Class

II, Division 1, Groups E,F, & G; And Class III, Division 1. Also Class I,

Division 2, Groups A,B,C, & D; Class II, Groups F & G; And Class III,

Division 2. Explosionproof For Class I, Division 1, Groups B,C, & D;

Dust-Ignitionproof For Class II, Division 1, Groups E,F,G; And Class III, Div

1.

|

|||

FM

Explosionproof For Class I, Division 1, Groups B,C, & D;

Dust-Ignitionproof For Class II, Division 1, Groups E,F,G; Class III,

Division 1. Also Nonincendive For Class I, Division 2, Groups A,B,C, & D;

Class II, Division 2, Groups F & G; Class III, Division 2.

|

|||

FM

FISCO/FNICO Field Device Intrinsically Safe For Class I, Division 1, Groups

A, B, C, & D; Class II, Division 1, Groups E,F, & G; And Class III,

Division 1. Class I, Division 2, Groups A,B,C, & D; Class II, Groups F

& G; And Class III, Division 2. Explosionproof For Class I, Division 1,

Groups B,C, & D; Dust-Ignitionproof For Class II, Division 1, Groups

E,F,G; And Class III, Div 1. Zone Certified AEx ia IIC And AEx n IIC.

|

|||

G

|

=

|

FM Zone

Certified Flameproof AEx d IIC. Also Explosionproof For Class I, Division 1,

Groups B,C & D And Dust-Ignitionproof For Class II, Division 1 Groups E,F

& G, And Class III, Division 1. Also Intrinsically Safe For Class I,

Division 1, Groups A,B,C & D; Class II, Division 1, Groups E,F & G;

And Class III, Division 1 And Class I, Division 2, Groups A,B,C, & D;

Class II, Groups F & G; And Class III, Division 2. Zone Certified

Intrinsically Safe AEx ia IIC And AEx n IIC.

|

|

WITH

(Electronic Version And Output Signal:T, V) And (Structure Code Materials And

Type:52, 53, 60, 61, 62, 63, D5, S5, SH, SJ) And (Conduit Connection &

Housing Material:1, 3)

|

|||

FM Zone

Certified Flameproof AEx d IIC. Also Explosionproof For Class I, Division 1,

Groups B,C & D And Dust-Ignitionproof For Class II, Division 1 Groups E,F

& G, And Class III, Division 1. Also Intrinsically Safe For Class I,

Division 1, Groups A,B,C & D; Class II, Division 1, Groups E,F & G;

And Class III, Division 1 And Class I, Division 2, Groups A,B,C, & D;

Class II, Groups F & G; And Class III, Division 2.

|

|||

FM Zone

Certified Flameproof AEx d IIC. Also Explosionproof For Class I, Division 1,

Groups B,C & D And Dust-Ignitionproof For Class II, Division 1 Groups E,F

& G, And Class III, Division 1. Also Nonincendive For Class I, Division

2, Groups A,B,C & D; Class II, Division 2, Groups F & G; And Class

III, Division 2.

|

|||

FM

FISCO/FNICO Field Device Zone Certified AEx ia IIC And AEx n IIC

Intrinsically SAfe And Zone Certified Flameproof AEx d IIC. Also

Intrinsically Safe For Class I, Division 1, Groups A, B, C, & D; Class

II, Division 1, Groups E,F, & G; And Class III, Division 1. Class I, Division

2, Groups A,B,C, & D; Class II, Groups F & G; And Class III, Division

2. Also Explosionproof For Class I, Division 1, Groups B,C, & D;

Dust-Ignitionproof For Class II, Division 1, Groups E,F,G; And Class III, Div

1.

|

|||

T

|

=

|

IECEx

Intrinsically Safe, FISCO Ex ia IIC T4

|

|

WITH

(Electronic Version And Output Signal:F)

|

|||

IECEx

Intrinsically Safe, Ex ia IIC T4

|

|||

U

|

=

|

IECEx

Intrinsically Safe, Protection n; FNICO Ex

|

|

WITH

(Electronic Version And Output Signal:F)

|

|||

IECEx

Intrinsically Safe, Protection n; Ex nL IIC T4

|

|||

V

|

=

|

IECEx

Flameproof, Ex d IIC T6

|

|

W

|

=

|

Multi Mark

(Intrinsic safe ONLY for FM, CSA & ATEX)

|

|

OPTIONAL MODEL SUFFIX(ES) INCLUDED: (a)

|

|||

M1

|

=

|

Painted

Steel Mounting Bracket With Plated Steel Bolts For Use With 1/2 NPT

|

|

M2

|

=

|

316 ss

Bracket with Stainless Steel Bolts for use with 1/2 NPT

|

|

M3

|

=

|

Painted

Steel Mounting Bracket With Plated Steel Bolts For Use With PG13.5

|

|

M4

|

=

|

316 ss

Bracket with Stainless Steel Bolts for use with PG13.5

|

|

M5

|

=

|

Painted

Steel Mounting Bracket With Plated Steel Bolts For Use With M20

|

|

M6

|

=

|

316 ss

Bracket with Stainless Steel Bolts for use with M20

|

|

M7

|

=

|

Mounting

Bracket SS Bracket & SS

|

|

M8

|

=

|

Mounting

Bracket Steel Bracket & Steel Hardware

|

|

L1

|

=

|

Digital

Indicator, Internal Pushbuttons, And Window Cover

|

|

WITH

(Conduit Connection & Housing Material:1, 2, 5)

|

|||

WITH

(Conduit Connection & Housing Material:3, 4, 6)

|

|||

L2

|

=

|

Blind

(Solid) Cover Over Standard LCD

|

|

S2

|

=

|

SIL2 TUV

Rhineland

|

|

A1

|

=

|

Hawke Type

Cable Gland

|

|

A2

|

=

|

Plastic

PG13.5 Connector

|

|

A3

|

=

|

M20

Connector

|

|

A4

|

=

|

Trumpet

Shaped PG13.5 Cable Gland (Nickel Plated Brass)

|

|

V1

|

=

|

Vent Screw

In Process Connection

|

|

V2

|

=

|

Block And

Bleed Valve - Carbon Steel

|

|

V3

|

=

|

Block And

Bleed Valve - 316 ss

|

|

V4

|

=

|

Block And

Bleed Valve - 316 ss Body w/Monel Trim

|

|

Z1

|

=

|

External

Zero Adjustment

|

|

Z2

|

=

|

Custody

Transfer Lock And Seal

|

|

Z3

|

=

|

External

Zero Adjustment And Custody Transfer Lock And Seal

|

|

C1

|

=

|

Digital

Output (4 To 20 mA Default If Not Selected)

|

|

C2

|

=

|

Full

Factory Configuration (Requires Configuration Form)

|

|

X1

|

=

|

Unit

Degreased (Not For Oxygen/Chlorine Service)

|

|

X2

|

=

|

Cleaned

And Prepared For Oxygen Service

|

|

X3

|

=

|

Cleaned

And Prepared For Chlorine Service

|

|

H1

|

=

|

Manifold

Attachment and Leak Tested

|

|

H2

|

=

|

Manifold

Attachment and Pressure Certificatiion

|

|

K1

|

=

|

Without

Instruction Book & CD

|

|

F1

|

=

|

Sanitary

Seal Finish RA15 or better

|

|

WITH

(Structure Code Materials And Type:TA)

|

|||

WITH

(Structure Code Materials And Type:T2)

|

|||

WITH

(Structure Code Materials And Type:T3)

|

|||

WITH

(Structure Code Materials And Type:TB)

|

|||

WITH

(Structure Code Materials And Type:T4)

|

|||

WITH

(Structure Code Materials And Type:T5)

|

|||

WITH

(Structure Code Materials And Type:M1)

|

|||

WITH

(Structure Code Materials And Type:M6)

|

|||

WITH

(Structure Code Materials And Type:M9)

|

|||

G

|

=

|

G 1/2 B

Manometer Process Connection

|

|

R

|

=

|

R 1/2

Process Connection (1/2 NPT To R 1/2)

|

|

T

|

=

|

Supplemental

Customer Tag

|

|

J

|

=

|

Low

Temperature Operative Limit Of -50°C (-58°F)

|

|

(a) Standard

transmitter (no K option specified) includes a paper instruction manual and a

full documentation set on a CD.

|

|||

(b) WirelessHART

Adaptors, Temperature Converters and Gateways can be ordered separately via

part numbers 217233, 217234, 211735, 220390, 211734, 219035 and 211749 .

|

|||

(c) User

supplied clamps and gaskets.

|

|||

(d) Supplied

with clamps and gaskets.

|

|||

(e) All

spuds (mounting ferrules) are accessories that are specified by part number.

All necessary mounting parts and gaskets to attach the transmitter to the

spud are supplied with the transmitter.

|

|||

(f) For

transmitter with Silicone Fill prepared for Direct Connect seal by others,

specify Structure Codes 22 or 52.

|

|||

(g) For

transmitter with Fluorinert Fill prepared for Direct Connect seal by others,

specify Structure Codes 23 or 53.

|

|||

(h) Electronics

version A, I, & V have LCD and Window Cover as standard. Only specify -L2

option to substitute solid cover for standard window cover.

|

|||

(i) Only

a brief "Getting Started" document is supplied.

|

|||

Đăng nhận xét Blogger Facebook